High Pressure Magmeters (Electromagnetic Flowmeter) is designed to measure the flow rates of conductive liquids in applications with high operating pressures.

It can be used in applications with pressures in excess of 6000 psig (42 Mpa), Line sizes ranging from 1" to 8" (25 mm to 200 mm) can be accommodated by the high pressured mag meter, with available process connections including ANSI, DIN, and JIS-type flanges.

A wide selection of options are also available for the display/converter module including Compact or remote type, 85-265 VAC or 16-36 VDC power, and HART, RS485 and Profibus communications.

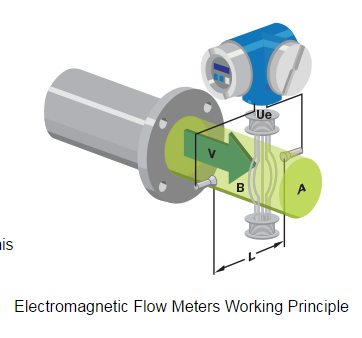

Faraday’s law of electromagnetic induction states that an inductive voltage is generated when a conductor moves through a magnetic field. This principle is used as the basis of flow measurement in the RBEF electromagnetic flow meter. In the electromagnetic flow meter, the flowing fluid corresponds to the moving conductor as described in Faraday’s law.

UE ∞ B * D * v

The induced voltage UE is directly proportional to magnetic field intensity (B), electrode spacing (D) and average fluid velocity (v). Since magnetic field intensity (B) and the electrode spacing (D) are constant values, induced voltage UE is therefore directly proportional to the average flow velocity (v).

Q = (∏ * D2) / 4 * v therefore UE ∞ Q

The equation for calculating volumetric flow rate (Q) shows that the induced voltage (UE) is linear and directly proportional to the average velocity (v). In the flowmeter transmitter, the induced voltage (UE) from the electrodes is used to calculate volumetric flow rate (Q) based upon the pipe’s internal diameter.

UE = Induced voltage

B = Magnetic field strength

D = Electrode spacing

V = Fluid velocity

Q = Instantaneous volumetric flow rate

High Pressure Magmeter (Emag.flow meter) Features:

High Pressure Magnetic Flow Meter(Magmeters) Specification:

|

Specification |

Data |

Specification |

Data |

|

Flow range |

0-12m/s |

Medium |

Conducting medium(Solid content ≤5%) |

|

Measuring repeatability |

± 0.1% |

Electrical Conductivity |

>5us/cm(water >20us/cm) |

|

Accuracy |

±0.5% |

Power |

220VAC/50Hz |

|

Pressure |

26MPa |

24VDC |

|

|

32MPa(special order) |

Output |

4-20mA |

|

|

Operation temp. |

0 to +80℃ |

Pulse |

0-1kHz(Adjustable) |

|

0 to + 45℃ |

Consumption |

10VA |

Dimensions

|

Pipe Size |

Working Pressure(MPa) |

a |

b |

c |

d |

Screw Size |

|

50 |

26 |

325 |

234 |

165 |

215 |

M24*8 |

|

65 |

26 |

330 |

256 |

190 |

246 |

M27*8 |

|

80 |

26 |

430 |

276 |

203 |

265 |

M30*8 |

|

100 |

26 |

440 |

308 |

241 |

310 |

M33*8 |

|

125 |

26 |

505 |

356 |

292 |

375 |

M39*8 |

Remark: 1. a is meter'length; b is Flange outside diameters; c is flange inside diameters; d is length of Magnetic Converter base to botton of pipe.

High Pressure Magnetic Flow Meter Model Selection

| RBEF Electromagnetic Flow Meter Model Selection | ||||||||||||||||||

| RBEF | ||||||||||||||||||

| [1] | [2] | [3] | [4] | [5] | [6] | [7] | [8] | [9] | [10] | [11] | [12] | [13] | [14] | |||||

| [1] | Category | Grounding & Lining Protection | ||||||||||||||||

| F | Flanged | C | Ceramic | Mini | Mini | [6] |

0 | Body-flange grounding (DN15 - DN1200) | ||||||||||

| W | Wafer-type | S | High-Frequency | Ex | Ex-proof | 1 | Ground ring [or lining protection flange] (DN15-DN250) | |||||||||||

| L | Threaded | B | Battery-Powered | I | Insertion | 2 | Grounding electrode (DN25 - DN1200) | |||||||||||

| K | Clamping | Hp | High-pressure | H | Energy | 3 | Import protection flange (DN50 - DN300) | |||||||||||

| [2] | Nominal Diameter(mm) | Ambient Temperature | ||||||||||||||||

| 003 | 065 | 400 | [7] | A | ≤80 ℃ (All lining) | |||||||||||||

| 006 | 080 | 450 | B | ≤120 ℃ (Only Neoprene、PTFE、PFA) | ||||||||||||||

| 010 | 100 | 500 | C | ≤180 ℃ (Only PTFE) | ||||||||||||||

| 015 | 125 | 600 | Protection& Anti-hazard Requirement | |||||||||||||||

| 020 | 150 | 700 | [8] |

1 | IP65 | |||||||||||||

| 025 | 200 | 800 | 2 | IP67 (Only compact) | ||||||||||||||

| 032 | 250 | 900 | 3 | IP68 (Only remote,tie cable should be specified) | ||||||||||||||

| 040 | 300 | 102 | 4 | IP65+Ex d ib mb IIC T4 Gb | ||||||||||||||

| 050 | 350 | 122 | Sensor And Converter Combination Structure | |||||||||||||||

| E.g. :050 = DN50; 150 = DN150; 122 = DN1200 | [9] | C | Compact(Only DN15-DN1000) | |||||||||||||||

| [3] | Nominal Pressure& Process Connection | R | Remote(With 10m signal cable, the other length is set separately) |

|||||||||||||||

| 02 | 0.25 MPa (DN700-DN1200) | |||||||||||||||||

| 06 | 0.6 MPa (DN700-DN1200) | Power Supply | ||||||||||||||||

| 10 | 1.0 MPa (DN200-DN1200) | [10] | A | Alternating current (85-265) VAC /(45-63)Hz | ||||||||||||||

| 16 | 1.6 MPa (DN15-DN600) | D | Direct current (16-36) VDC | |||||||||||||||

| 20 | ANSI 150 (DN15-DN600) | B | Battery 3.6 VDC | |||||||||||||||

| 40 | 4.0 Mpa (DN 3-DN150) | Output Signal & Input Signal | ||||||||||||||||

| 50 | ANSI 300 (DN15-DN600) | [11] | 0 | Basic configuration (Current output + pulse output + alarm output) |

||||||||||||||

| 91 | JIS 10K (DN15-DN600) | |||||||||||||||||

| 92 | JIS 20K (DN15-DN600) | 2 | Basic configuration + RS232 | |||||||||||||||

| 93 | Fixed-length model AMAG- I | 4 | Basic configuration + RS485 | |||||||||||||||

| 94 | Pluggable Model AMAG- I-500 | M | Basic configuration + MODBUS | |||||||||||||||

| 95 | Pluggable Model AMAG- I-900 | H | Basic configuration + HART | |||||||||||||||

| 99 | Special pressure requirements(According to special order form) |

P | Basic configuration + Profibus-DP | |||||||||||||||

| Additional Function | ||||||||||||||||||

| [4] | Lining Material | [12] | O | No requirement | J | Relay output | ||||||||||||

| 1 | Soft Neoprene (≤ DN1200) | T | Power-off recording | F | Enhancements | |||||||||||||

| 2 | Hard Neoprene (≤ DN1200) | Q | Quantitative control | S | High-Frequency | |||||||||||||

| 3 | PTFE (≤ DN1000) | R | Infrared remote control | G | GPRS communication | |||||||||||||

| 4 | Polyurethane (≤ DN300) | H | Hourly accumulation | L | Ultralow temperatureconverter | |||||||||||||

| 5 | PFA (≤ DN250) | Factory Inspection (Accuracy Level & Flow Point Number) | ||||||||||||||||

| 6 | F46 (≤ DN250) | [13] | 1 | 0.5 level、3 point check | 3 | 0.5 level、5 point check | ||||||||||||

| 7 | Ceramics (≤ DN250) | 2 | 0.2 level、3 point check | T | Other requirement | |||||||||||||

| [5] | Electrode Material | Supplementary | ||||||||||||||||

| 1 | Stainless steel [316L] | [14] |

0 | No requirement | ||||||||||||||

| 2 | Hastelloy C [Alloy-C22] | 1 | Stainless steel 304SS sensor(304SS flange) | |||||||||||||||

| 3 | Hastelloy B [Alloy-B10] | 2 | Special requirements 1 (According to special order form)* | |||||||||||||||

| 4 | Titanium | 3 | Special requirements 2 (According to special order form) ** | |||||||||||||||

| 5 | tantalum | Selection E.g. | ||||||||||||||||

| 6 | Platinum/iridium Alloy | Flange type, DN150, 4 .0MPa, PTFE lining, Hastelloy alloy C electrode, body flange grounding, ambient temperature < 120℃, IP65 non-ex-proof,compact,AC power supply, basic configuration + RS485, no additional functional requirements, 0.5 level,3 point check, stainless steel sensor .Selection coding:RBEF-F15040320B1CA4011 |

||||||||||||||||

| 7 | Stainless steel coated tungsten carbide | |||||||||||||||||

| 8 | Special conductive ceramics (Only for ceramic lining ) | |||||||||||||||||

| * | E.g. :[14]=2,Marked 316SS flange, 304SS sensor shell. | |||||||||||||||||

| ** |

E.g. :[14]=3, Marked 316SS flange, 304SS sensor shell.

|

|||||||||||||||||

|

|

High Pressure Electromagnetic Flowmeter Typical applications:

Magmeters

Ultrassonic Flow Meter

Coriolis, Thermal Mass Flow Meter

Other Process Instrument