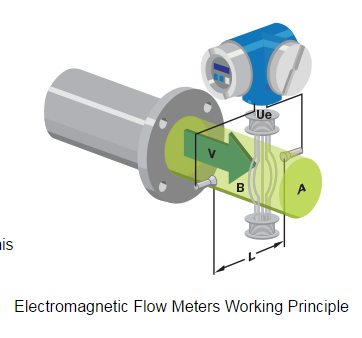

The RBEF-E Mini Inductive Magnetic flow meter extremely compact, low cost, inductive magnetic flow meter(including Transmitter and sensor), the Mini Inductive Magnetic flow meter is the perfect solution for measuring the flow of conductive liquids in applications where reliability and low-pressure loss of a magmeter are desired at an economical price compared to higher end models. This magmeter measures flow using the magnetic-inductive principle. According to Faraday’s law of magnetic induction, current is induced into a conductor as it moves through a magnetic field. The amount of current induced is directly proportional to the velocity of the moving conductor. A conductive liquid passing through the flowmeter body acts as the conductor. The flowmeter body contains a set of electromagnetic coils that generate the magnetic field. Electrodes mounted in the flowmeter body collect the current, whose magnitude is proportional to flow rate.

RBEF-E Mini Inductive Magnetic flow meter is special designed liquid flow monitoring in industrial processes such as for food and beverages, Chemical and Pharmaceutical filling controller, plumbing applications.

The Magmeters is ideal for use in the field of mechanical engineering and plant construction, No Moving Parts, RS485, Frequency and 4 to 20 mA Output, Maintenance-Free, Minimum inlet section requirements and the instrument is available in three different sizes. All Inductive Magnetic flow meters will be delivered with a works calibration certificate.

The magnetic flow meter, also technically an electromagnetic flow meter or more commonly just called a mag meter. A magnetic field is applied to the metering tube, which results in a potential difference proportional to the flow velocity perpendicular to the flux lines. The physical principle at work is electromagnetic induction. The magnetic flow meter requires a conducting fluid, for example, water that contains ions, and an electrical insulating pipe surface, for example, a rubber-lined steel tube.

If the magnetic field direction were constant, electrochemical and other effects at the electrodes would make the potential difference difficult to distinguish from the fluid flow induced potential difference. To mitigate this in modern magnetic flowmeters, the magnetic field is constantly reversed, cancelling out the electrochemical potential difference, which does not change direction with the magnetic field. This however prevents the use of permanent magnets for magnetic flowmeters.

RBEF-E Mini Inductive Magnetic flow meter Features:

RBEF-E Mini Inductive Magnetic flow meter technical Specification:

RBEF-E Mini Inductive Magnetic flow meter Model Selection:

|

RBEF- |

DN |

- |

|

- |

|

- |

|

- |

|

- |

|

- |

|

- |

|

- |

|

- |

|

- |

|

- |

|

- |

|

- |

|

|

|

|

1 |

|

2 |

|

3 |

|

4 |

|

5 |

|

6 |

|

7 |

|

8 |

|

9 |

|

10 |

|

11 |

|

12 |

|

13 |

|

14 |

15 |

|

1 Nominal Diameter(mm)/ [inches] (1)

|

||||||||||

|

2 Flange Rating (1)

|

||||||||||

|

3 Electrode Material

|

||||||||||

|

4 Lining Material

|

||||||||||

|

5 Grounding and Lining Protection

|

||||||||||

|

6 Max. Process Temperature

|

||||||||||

|

7 Environmental Protection Class

|

||||||||||

|

8 Explosion Proofing

|

||||||||||

|

9 Configuration – sensor/transmitter

|

||||||||||

|

10 Power Supply

|

||||||||||

|

11 Display and Programming

|

||||||||||

|

12 Output and Input

|

||||||||||

|

|

||||||||||

|

13 Calibration Specification

|

||||||||||

|

14 Flow Tube Configuration

|

15 Special Function

|

0 |

No |

R |

IR Remote |

|

T |

Power off timer |

H |

Cumulative hours |

|

Q |

Quantitative control |

J |

Relay Output |

RBEF-E Mini Inductive Magnetic flow meter Applications

Modular dosing system for filling conductive liquids in packaging machinery(flow meter filling machine)

Water

Soft drinks

Milk and Dairy

Beer

Fruit juices and other fluids with fibres

Magmeters

Ultrassonic Flow Meter

Coriolis Mass Flow Meter

Other Flow Instrument